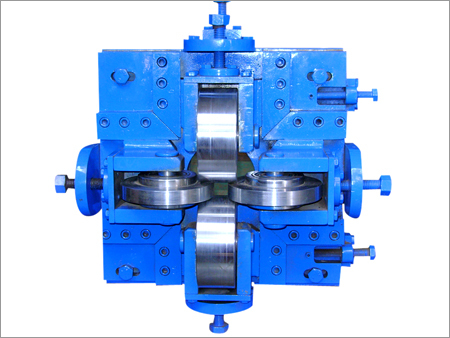

High Speed Tube Mills

10000000 INR/Unit

Product Details:

- Country Of Origin India

- Frequency 50 Hertz (HZ)

- Power Source Electricity

- Surface Treatment Painted

- Warranty 1 Year

- Usage & Applications Industrial

- Click to View more

X

High Speed Tube Mills Price And Quantity

- 1 , , Unit

- 10000000 INR/Unit

High Speed Tube Mills Product Specifications

- 50 Hertz (HZ)

- Industrial

- India

- Electricity

- 1 Year

- Painted

High Speed Tube Mills Trade Information

- 1 , , Unit Per Day

- 3 Months

- All India

Product Description

Having immense experience in our functional domain, we are instrumental in providing a superior quality Tube Mill Plant to our client across the globe. This plant is manufactured with accuracy to meet the defined international standards by utilizing optimum quality components and advanced technology. Provided plant is used for making different types of pipes for industrial purposes and can be availed with different technical specifications. We offer this Tube Mill Plant at a marginal price range.

Features:

-

Durable finish standards

-

High performance

-

Noise-free operations

-

Long service life

PLC Controlled Automation

These tube mills utilize sophisticated PLC control systems to automate the production process. With computerized supervision, operators benefit from seamless setup, tracking, and adjustments, resulting in reduced errors and consistent product quality. Automation also contributes to faster throughput and improved operational safety.

Robust Mechanical Drive

The mechanical drive type matched with a powerful 200 HP rating ensures long-lasting durability and stable performance. This technology enhances tube forming efficiency, minimizing downtime and maximizing output in demanding manufacturing environments.

FAQs of High Speed Tube Mills:

Q: How does the computerized PLC control system benefit tube mill operations?

A: The computerized PLC control system automates production, monitors key parameters, and allows real-time adjustments. This leads to improved accuracy, faster changeovers, and reduced human intervention, which enhances overall productivity and quality.Q: What is the process for using a High Speed Tube Mill in manufacturing MS tubes?

A: The process typically involves feeding MS material into the mill, which is then shaped, welded, and cut to size automatically under PLC supervision. The mechanical drive ensures the proper movement and formation of tubes at high speed.Q: When should regular maintenance be performed on the tube mill?

A: Routine maintenance should be scheduled based on operational hours and manufacturers guidelines, often every few months. Regular checks ensure optimal performance and longevity, reducing the risk of unexpected downtime.Q: Where can High Speed Tube Mills be sourced in India?

A: These tube mills are available from distributors, exporters, manufacturers, suppliers, and wholesalers across India. Many industrial equipment providers offer both new installations and after-sales support throughout the country.Q: What are the main usage applications of these tube mills?

A: High Speed Tube Mills are primarily used for producing mild steel tubes that serve construction, automotive, furniture, and other industrial sectors requiring precise and durable tubing solutions.Q: What advantages does the automatic grade feature provide to manufacturers?

A: Automatic grade operation streamlines tube production, reduces operator fatigue, and facilitates high-volume processing with consistent results, contributing to overall efficiency and competitiveness in manufacturing.Q: What warranty and support services are offered with these tube mills?

A: High Speed Tube Mills come with a 1-year warranty, covering major mechanical and control system components. Customers also benefit from technical assistance and after-sales services provided by suppliers and manufacturers in India.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS