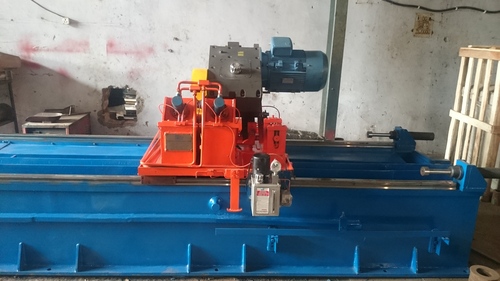

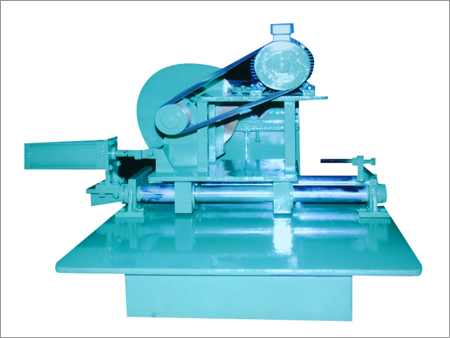

Big Cold Saw

1200000 INR/Unit

Product Details:

- Cutting Accuracy 0.05 mm

- Cutting Speed Up to 80 m/min

- Coating Type Carbide

- Tool Type Saw Blade

- Material High-Speed Steel (HSS)

- Cutting Force 2200 N

- Operate Method Automatic

- Click to View more

X

Big Cold Saw Price And Quantity

- 1 Unit

- 1200000 INR/Unit

- Emergency stop, protective guards

- Heavy-duty welded steel

- 380V/50Hz

- 25120 rpm variable

- Hydraulic

- 7.5 kW

- 950 kg

- 1200 mm

- Metal Pipe and Bar Cutting

- Integrated

Big Cold Saw Product Specifications

- Automatic

- HRC 6265

- 650 Nm

- 2200 N

- Saw Blade

- High-Speed Steel (HSS)

- Carbide

- Up to 80 m/min

- 0.05 mm

- 350 mm

- Round

- Cold Sawing

- Semi-Automatic

- 2.5 meters (machine length)

- Low noise, high precision, quick blade change

- Max 350 mm diameter

- Cold Saw Machine

- Carbide Coated

- Circular Cutter

- Emergency stop, protective guards

- Heavy-duty welded steel

- 380V/50Hz

- 25120 rpm variable

- Hydraulic

- 7.5 kW

- 950 kg

- 1200 mm

- Metal Pipe and Bar Cutting

- Integrated

Big Cold Saw Trade Information

- Cash on Delivery (COD), Letter of Credit (L/C), Paypal, Western Union, Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 1 Unit Per Day

- 3 Months

- All India

Product Description

BIG COLD SAW

An essential part of the tube mill, which enables cutting of the tube to the preset length by a cut off machine. The function of that equipment determines the overall productivity. The metal saw cut off system can easily handle all types of products - circular, square and rectangular. The synchronization is achieved with the use of AC Servomotor control system for fastest response time and best results. This is an online milling operation.

High Precision Cutting Performance

Maintain exceptional accuracy with a cutting tolerance of 0.05 mm. The Big Cold Saws robust carbide-coated blade and automatic operation consistently deliver clean, smooth cuts at speeds up to 80 m/min, ideal for both round metal pipes and bars.

Dependable Construction and Safety

Featuring a heavy-duty welded steel frame and a 1200 mm infeed table, this machine promises stability during intense workloads. Safety is ensured through integrated emergency stop buttons and protective guards, making high-volume cutting safer for operators.

Efficient Operation and Maintenance

Designed for semi-automatic operation, the Big Cold Saw streamlines the cutting process, reducing manual intervention. Hydraulic clamping and rapid blade change functions optimize productivity, while the integrated coolant system extends blade life and maintains temperature control.

FAQs of Big Cold Saw:

Q: How does the hydraulic clamping system enhance the cutting process?

A: The hydraulic clamping system securely immobilizes the metal pipe or bar, preventing movement during cutting for improved precision and safety. This ensures consistent results and minimizes material wastage.Q: What types of materials can the Big Cold Saw cut?

A: It is specially designed for high-speed steel (HSS) and can handle round metal pipes and bars with diameters up to 350 mm, making it versatile for metalworking applications.Q: When should the saw blade be changed or maintained?

A: Blade maintenance or replacement is recommended if cutting accuracy declines, if theres visible wear on the carbide coating, or after extensive use. The machines quick blade change feature allows fast, efficient maintenance.Q: Where is the Big Cold Saw best utilized?

A: This machine excels in metal fabrication shops, industrial manufacturing plants, and distributor facilities, particularly where high-volume, precise cutting of pipes and bars is required.Q: What process does the Big Cold Saw use for cutting?

A: It utilizes a cold sawing process with a circular cutter, which minimizes heat distortion and preserves the integrity of the materials structure, perfect for precision metalwork.Q: How does the integrated coolant system benefit usage?

A: The coolant system keeps the blade and material cool, reducing wear and prolonging blade life, while also preventing overheating and ensuring consistent cutting quality.Q: What are the main benefits for distributors or manufacturers using this machine?

A: Users benefit from high cutting accuracy, quick blade changes, reliable safety features, and low operational noise, all of which support efficient, large-scale production with minimal downtime.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS