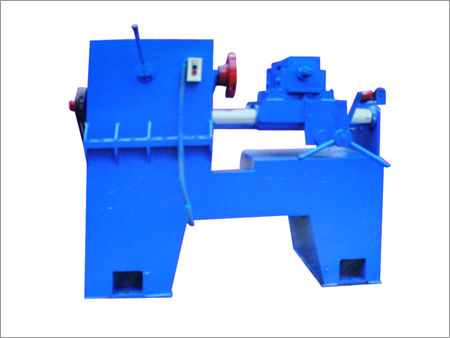

End Facing Machine

1200000 INR/Unit

Product Details:

- Torque High Torque Output

- Diameter Pipe OD 50 mm to 200 mm

- Shape Rectangular Base with Cylindrical Spindle

- Phase Three Phase

- Product Type End Facing Machine

- General Use Pipe and Tube End Facing

- Material MS / SS (Mild Steel / Stainless Steel)

- Click to View more

X

End Facing Machine Price And Quantity

- 1200000 INR/Unit

- 1 Unit

End Facing Machine Product Specifications

- 400 kg (Approx.)

- Powder Coated

- Available on Request

- High Torque Output

- 0.05 mm

- End Facing Machine

- Manual / Electric Control Panel

- Rectangular Base with Cylindrical Spindle

- Low Noise Operation, Easy Tool Changeover, Rigid Construction

- Pipe OD 50 mm to 200 mm

- 415V AC, 3 Phase, 50 Hz

- Tube End Facing

- MS / SS (Mild Steel / Stainless Steel)

- Pipe and Tube End Facing

- Industrial Grey

- 1600 mm x 1000 mm x 1300 mm

- No

- No

- Three Phase

- 50 mm to 200 mm OD

End Facing Machine Trade Information

- 1 Unit Per Day

- 3 Months

- Australia, North America, South America, Eastern Europe, Middle East, Africa, Central America, Western Europe, Asia

- All India

Product Description

By keeping track on growing demand of the market, we have engaged in manufacturing, exporting an supplying optimum quality End Facing Machine that is widely used to cut the bevels on thin or heavy wall pipe ends for welding purposes. This machine is manufactured by utilizing supreme quality components and advanced technology under the proper guidance of our team of deft professionals. Available in different technical specifications, our clients can avail this End Facing Machine in at an affordable price range.

Features:

-

Low energy consumption

-

Durable finish standards

-

Negligible maintenance

-

Longer service life

Precision End Facing for Pipes and Tubes

This machine excels in producing consistently accurate end faces on pipes and tubes, boasting a tight tolerance of 0.05 mm. Suited for both mild steel and stainless steel, it effectively serves industries requiring high-quality, dependable edge preparation on materials with diameters between 50 mm and 200 mm.

Durable Construction and Efficient Operation

With a rugged powder-coated body, the End Facing Machine ensures rigidity and long-term resistance to workplace wear and tear. Its design emphasizes low noise output and swift tool changeovers, making it a practical addition to any fabrication or pipework facility.

FAQs of End Facing Machine:

Q: How do you operate the End Facing Machine without computerized controls?

A: The machine utilizes a manual or electric control panel for all its operations, ensuring straightforward use without the need for complex programming. Operators can easily adjust settings and oversee the end facing process directly from the control panel.Q: What is the recommended application range for this End Facing Machine?

A: This machine is best used for pipe and tube end facing in the 50 mm to 200 mm outer diameter range, accommodating both mild steel (MS) and stainless steel (SS) materials. It delivers high-precision results across a variety of industrial and fabrication settings.Q: When should I request a drawing for the End Facing Machine?

A: Drawings should be requested if you require detailed machine specifications for planning installations, custom fitting, or approval processes. Distributors, exporters, manufacturers, and suppliers can provide these upon request.Q: Where is the End Facing Machine manufactured and distributed?

A: The End Facing Machine is manufactured, supplied, and exported from India and is distributed by a network of wholesalers and suppliers to domestic and international markets.Q: What are the key benefits of using this End Facing Machine in my workshop?

A: Key advantages include low noise operation, precise end finishing (tolerance of 0.05 mm), rapid and easy tool changeover, and robust, powder-coated construction for durability. It supports high workloads with a powerful torque output to handle tough materials efficiently.Q: How does the machine ensure easy maintenance and tool changeover?

A: The design allows for straightforward access to tooling components, which minimizes downtime during tool changes. Routine maintenance is simple thanks to its rigid construction and accessible layout.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS