HR & CR Tube Mills

1200000 INR/Unit

Product Details:

- Machine Type Horizontal Tube Mill

- Frame Type Heavy Duty Modular Frame

- Connectivity Options Remote Monitoring (Optional)

- Accuracy 0.02 mm

- Model No HTM-CR/HR Series

- Power Rating Custom as per requirement

- Control System PLC Controlled

- Click to View more

X

HR & CR Tube Mills Price And Quantity

- 1200000 INR/Unit

- 1 Unit

HR & CR Tube Mills Product Specifications

- 100 kW - 350 kW (depending on model)

- Automatic

- Low

- 380V/415V, 3 Phase

- Water Circulation

- Polished, Galvanized, Heat Treated

- HTM-CR/HR Series

- PLC Controlled

- Custom as per requirement

- Remote Monitoring (Optional)

- 0.02 mm

- 18000 to 50000 kg (approx.)

- HR & CR Tube Mills

- Green/Blue/Custom

- Manufacturing of HR/CR Tubes & Pipes, Structural Steel, Automotive Components

- Heavy Duty Modular Frame

- Horizontal Tube Mill

- Standard

- AC Motor with Gearbox

- Electric

- Up to 100 tons/day

- Varies (Customized as per requirement)

- Advanced Automated Rolling

- Centralized Automatic Lubrication

- 50/60 Hz

- Up to 350 kW

- Ambient to 45C

- High Precision, Low Maintenance, Robust Construction, Energy Efficient

HR & CR Tube Mills Trade Information

- 1 Unit Per Day

- 3 Months

- All India

Product Description

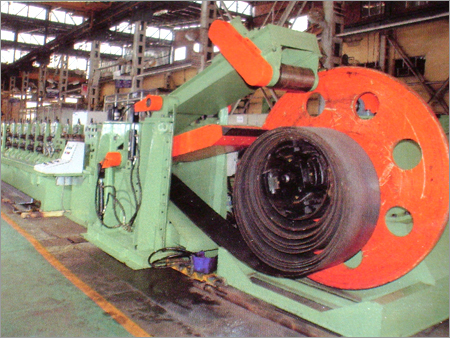

For our distinguished and treasured clients, we are immersed in manufacturing, exporting and supplying superior quality Hs Tube Mill. This mill is manufactured using premium quality components and contemporary techniques under the guidance of our skilled professionals in compliance with set industry norms. Our provided mill is mainly used in steel industry for the production of several carbon steel products and is highly appreciated for its sturdy design. Also, the offered Hs Tube Mill can be availed in numerous specifications as per client need at marginal rates.

Features:

-

Sturdy construction

-

Optimum performance

-

Easy to operate

-

Silent operations

Advanced Automation for Consistency

The tube mills incorporate PLC-controlled systems and touchscreen HMI for seamless operation, enabling consistent tube production with minimal manual intervention. Automatic features such as central lubrication, remote monitoring options, and integrated safety systems enhance both efficiency and operator safety.

Versatile and Customizable Performance

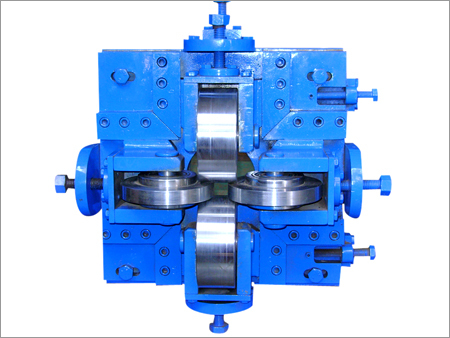

Supporting a wide range of coil widths (50650 mm), thicknesses (0.512 mm), and tube diameters (12219 mm), these mills can be configured with 1428 forming stands, 5/7-roll straightening units, inkjet/stamping marking systems, and various cut-off options. Every machine is tailored to suit specific manufacturing needs.

Comprehensive Installation and Support

Our team provides onsite installation, commissioning, and training for operators, ensuring smooth startup. Both remote and onsite service support are available across India and abroad, minimizing downtime and optimizing long-term productivity for industrial tube manufacturing.

FAQs of HR & CR Tube Mills:

Q: How are the roll sets of the HR & CR Tube Mills manufactured and what material is used?

A: The roll sets are crafted from alloy steel and undergo heat treatment to ensure durability and consistent tube forming. This construction ensures long-lasting performance even when handling varied thicknesses and diameters.Q: What is the process for forming and welding tubes in these mills?

A: Initially, HR/CR coils are loaded onto the powered uncoiler, followed by precision edge milling and progressive tube forming across 1428 stands. High frequency induction welding ensures strong seam joints, and the integrated cold or flying saw provides accurate cut-to-length results.Q: When is onsite installation and commissioning available for these machines?

A: Onsite installation and commissioning are scheduled at the time of purchase, coordinated between our service team and the client to fit production plans. Operator training is conducted during installation to streamline adoption.Q: Where are these tube mills typically used and what applications do they cover?

A: These tube mills are widely used in India and internationally for manufacturing structural steel tubes, pipes, automotive parts, and other industrial components. Their robust and automated operation makes them suitable for high-volume production environments.Q: What are the key benefits of using HTM-CR/HR Series Tube Mills?

A: Key advantages include high precision (accuracy up to 0.02 mm), efficient automated operation, low maintenance, robust construction, and energy efficiency. This ensures superior product quality, reduced downtime, and cost-effective manufacturing.Q: How many operators are required per shift to run the tube mill efficiently?

A: Typically, only 12 skilled operators are needed per shift due to the advanced automation system and centralized control, which streamlines most production and monitoring tasks through the HMI interface.Q: What safety and environmental features are included in these tube mills?

A: Safety is ensured with emergency stop, interlock guarding, and overload protection systems. The mills comply with international environmental standards and are equipped with low-noise, energy-efficient features and enclosed cooling and lubrication systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS